Foundation of FBS blocks: material characteristics, features and options for performing work

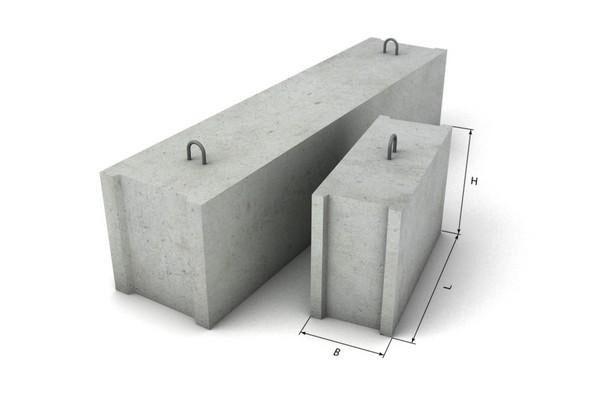

For the construction of a private house or cottage, many owners choose a foundation made of FBS blocks as the base, which is well suited for small one-story buildings. Unlike other options, it installs faster and more conveniently, although it requires the use of a truck crane to install heavy blocks. The abbreviation "FBS" stands for "wall foundation block", by which the main purpose of this building material becomes clear.

For the construction of a private house or cottage, many owners choose a foundation made of FBS blocks as the base, which is well suited for small one-story buildings. Unlike other options, it installs faster and more conveniently, although it requires the use of a truck crane to install heavy blocks. The abbreviation "FBS" stands for "wall foundation block", by which the main purpose of this building material becomes clear.

What is the foundation of FBS blocks

The most common are the following standard sizes:

- 280x300x279 mm. (80 kg);

- 380x300x580 mm. (100 kg).

Both types are well suited for the construction of prefabricated foundations, therefore they are widely used in low-rise construction of country houses. Despite the fact that the budget for the construction of such a foundation does not differ much from the traditional one strip base, a block foundation from ready-made blocks is erected faster. Thus, the terms of delivery of the finished construction object are reduced, which makes it possible for the owners to quickly move into the finished house.

Wall FBS should be purchased only from a reliable manufacturer who can provide a quality certificate for finished reinforced concrete structures. This will give confidence in their compliance with the strict regulatory requirements of GOST 13579-78.

In terms of the strength of the FBS, the blocks are slightly inferior to monolithic reinforced concrete foundations, but they can be used for a one-story structure. Such a base is perfect for houses built of clay bricks, shell stones, foam and aerated concrete blocks, as well as profiled beams. When erecting a foundation from FBS blocks, it is not required to wait for the concrete to harden, since the blocks are delivered to the construction site ready-made.

All blocks are necessarily fastened together with a cement-sand composition, which ensures the sealing of all cracks and gives the tape solidity.

The main advantages of FBS blocks

When choosing a material for the construction of a foundation, it must be remembered that for FBS blocks:

When choosing a material for the construction of a foundation, it must be remembered that for FBS blocks:

- high speed of laying the base;

- no need to install formwork;

- not the influence of weather conditions, since the plates can be mounted at any time (snow and rain are not an obstacle to work);

- the ability to use on almost any type of soil;

- high quality of finished concrete structures (strength, fracture resistance).

In order to objectively evaluate such blocks, one should also say about some of the disadvantages that are inherent in this material.

Fortunately, there are not so many of them, however, it is important to know about them:

- The need to use special equipment.

- Difficulty with cutting a concrete FBS slab, since it has a high density.

To organize the construction of such a foundation, a team of several people will be required, and here it is important to strictly observe safety precautions.

Features of the construction of the base from blocks

It should be understood that only the correct foundation of the FBS blocks can guarantee:

It should be understood that only the correct foundation of the FBS blocks can guarantee:

- its strength and durability;

- resistance to the negative effects of high humidity and other factors.

Such a base is best suited for sandy soils, however, building codes allow the use of FBS blocks on clay soils. The only thing is that it is important to deepen the base enough to prevent the foundation from being pushed out due to freezing of the soil.

Despite the fact that the blocks are made of heavy concrete, the material is porous, so excess moisture can harm it and impair its bearing capacity. For this reason, the foundations of FBS blocks for low-rise buildings must be waterproofed with special materials or liquid bitumen compositions. Thanks to this, the service life of the foundation, and therefore the structure as a whole, will be maximum.

FBS blocks can be used not only for the construction of the foundation, but also for the walls. It is thanks to this that the house acquires exceptional strength and resistance to high loads.

Step-by-step instructions for building a foundation from FBS blocks

If you are going to do the installation of the FBS with your own hands, the owner must draw up a project without fail. It will reflect information about the dimensions of the foundation and its configuration.

If you are going to do the installation of the FBS with your own hands, the owner must draw up a project without fail. It will reflect information about the dimensions of the foundation and its configuration.

It is best to use special programs for these purposes. They make it possible to calculate the required number of FBS blocks with high accuracy.

In addition, the following should be taken into account:

- type of soil;

- groundwater level;

- the depth of the trench for laying FBS blocks;

- availability of access roads for equipment (truck crane).

If we refer to the step-by-step instructions for the foundation of FBS blocks, then there are several stages. Each of them should be approached responsibly.

Excavation

The first stage is the implementation of earthworks. It cleans up excess debris and unnecessary materials from the jobsite. Next, the markup is performed in kind. It includes the installation of pegs and the tension of the line along the internal and external dimensions of the blocks. The depth of the FBS is on average 0.8-1 meter. The depth depends on the level of soil freezing.

The first stage is the implementation of earthworks. It cleans up excess debris and unnecessary materials from the jobsite. Next, the markup is performed in kind. It includes the installation of pegs and the tension of the line along the internal and external dimensions of the blocks. The depth of the FBS is on average 0.8-1 meter. The depth depends on the level of soil freezing.

In the inner space, it is recommended to remove the level of fertile soil to a depth of 10-15 cm.Then fill this place with rubble or gravel

When building a foundation from FBS blocks, you should very responsibly approach the formation of the sole. The stability of the blocks and their immobility will depend on this. On hard soils, sand and gravel bedding is usually performed, 10-15 cm thick. Moistening and compaction of the first layer is mandatory. If the soil is soft or heaving (clay), then it is recommended to make a concrete pad, which is poured with mortar and reinforced.

If the pillow is being poured, it will be necessary to wait 21 days for the final hardening of the concrete solution.

Installation of FBS blocks

When the base is ready, proceed to the direct installation of the prefabricated strip foundation from the FBS blocks. Installation is carried out using a construction crane, which places the material in the right places. During the process, workers adjust the locations of the blocks. The blocks are fixed to each other with a cement-sand mortar. The consumption rate is about 10-15 liters. mixtures for 1 block.

When the base is ready, proceed to the direct installation of the prefabricated strip foundation from the FBS blocks. Installation is carried out using a construction crane, which places the material in the right places. During the process, workers adjust the locations of the blocks. The blocks are fixed to each other with a cement-sand mortar. The consumption rate is about 10-15 liters. mixtures for 1 block.

Work requires precision and care. All slabs must be installed exactly according to the marks, which will allow you to precisely observe the geometry of the structure. Along the way, you should immediately fill up all the cracks in the blocks for the foundation. This will eliminate the accidental formation of unnecessary voids.

Waterproofing

To eliminate the negative effect of moisture on the FBS blocks, they must be waterproofed without fail. For these purposes, a liquid bitumen-based mastic is usually used. It is applied to the entire lower part of the concrete base. In this case, both the outer and inner walls of the blocks should be processed. This is simply necessary to obtain a solid foundation.

To eliminate the negative effect of moisture on the FBS blocks, they must be waterproofed without fail. For these purposes, a liquid bitumen-based mastic is usually used. It is applied to the entire lower part of the concrete base. In this case, both the outer and inner walls of the blocks should be processed. This is simply necessary to obtain a solid foundation.

In regions with increased rainfall, roofing material sheets can be used as an additional waterproofing layer.

Based on the foregoing, we can conclude that a strip foundation made of concrete FBS blocks makes it possible to obtain a solid and reliable foundation for small one-story buildings. The most important thing is to strictly adhere to the technology and sequence of construction work. Pay attention to the purchase of blocks, as well as competently organize all the work. Practice confirms that such a foundation lasts for a long time. Knowing how to build a foundation from blocks correctly, a person can get a foundation that will become a reliable support for a future private house or cottage.