Machine for sharpening blunt chainsaws

For comfortable work and even cuts, you need not only a high-quality and powerful tool, but also a sharp chain. You can sharpen it manually with files or a chain sharpening machine for chainsaws. The first method is perfect if you just need to sharpen the blunt blades of the teeth, without changing anything in them. But if the teeth have lost their shape, it will be difficult and time-consuming to process them manually. Therefore, in this case, it is better to use sharpening machines, they will help to sharpen all the teeth correctly and evenly.

For comfortable work and even cuts, you need not only a high-quality and powerful tool, but also a sharp chain. You can sharpen it manually with files or a chain sharpening machine for chainsaws. The first method is perfect if you just need to sharpen the blunt blades of the teeth, without changing anything in them. But if the teeth have lost their shape, it will be difficult and time-consuming to process them manually. Therefore, in this case, it is better to use sharpening machines, they will help to sharpen all the teeth correctly and evenly.

Before using any tool for sharpening a chainsaw chain, you must read the instructions, follow the operating rules and safety precautions.

Types and advantages of machines

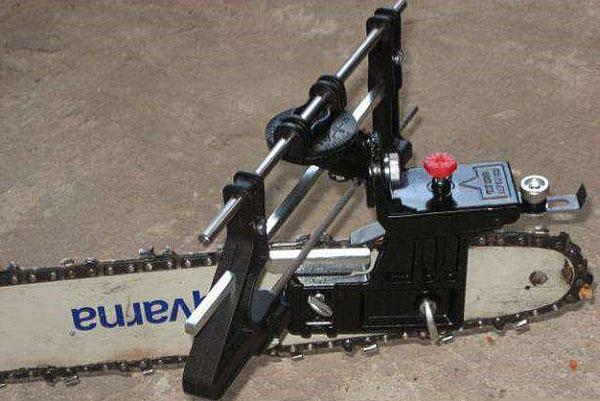

Sharpening machines are available manual and automatic, each of them has its positive and negative sides. Manual devices are divided into stationary and mobile. The former are installed on a table or other surface, and the latter are installed directly on the tire of the chainsaw. In the end, you don't need to remove the chain. Mobile chainsaw sharpeners are attached to the rail with screws on both sides. The tool has a scale with degree markings, where the required sharpening angle is set.

When buying a hand-held machine, keep in mind that files are often not included in its kit, since their size depends on the type of chain.

- the cost is much lower than that of the automatic;

- the teeth are sharpened efficiently and in the same way, since the settings are set only once and for the most damaged of them;

- operation does not require connection to the electrical network;

- safe to operate;

- a chain sharpened by hand has a longer service life than one sharpened by an electric tool.

The main thing is to correctly determine the desired angle depending on the purpose of the chain. A table of sharpening angles is always attached to high-quality manual chain saws.

All teeth must be of the same height so that the load on the chain is evenly distributed. If one of the teeth is noticeably lower, then the risk that the chain will break in this place is extremely high.

The disadvantages of hand tools can be attributed only to the long processing time of the equipment.

Automatic machines

The electric chainsaw sharpener looks like a circular saw, but is mounted on a frame. It houses a motor, a handle, a grinding wheel with a protective cover - all together they are called a movable working head. Also on the machine there are screws for adjusting the sharpening angles, depth, support and chain retainer, and on the bottom there is a scale for setting the rear angle.

The advantages of electric machine tools:

The advantages of electric machine tools:

- sharpening will take much less time than if done by hand;

- with the correct selection of parameters and compliance with the rules of operation, all teeth will be exactly the same;

- are compact and lightweight;

- simple operation.

The main disadvantage is that the chain grinds faster than when processing with a handheld device. Do not overload the engine for too long, otherwise it will lead to overheating. Electricity is required for work.

You should buy an automatic machine when you need to frequently process a large amount of tooling. It is also essential for carbide chains that cannot be sharpened with a manual chain sharpening kit.

Sharpening technology and how to know what to sharpen a chain

Signs by which you can determine that the teeth have become blunt:

Signs by which you can determine that the teeth have become blunt:

- the chainsaw vibrates strongly, gets stuck and tries to escape from the hands;

- cutting time is required longer than usual;

- increased fuel consumption;

- the shavings became fine.

The sooner the processing is carried out, the less metal needs to be removed, which means that the chain will last much longer.

The sooner the processing is carried out, the less metal needs to be removed, which means that the chain will last much longer.

Before starting work, you need to select the smallest prong. All parameters are adjusted according to it so that all the teeth are the same.

Step-by-step instructions on how to sharpen a chain on an automatic machine with your own hands:

- The screw clamping the equipment is unscrewed, and it is removed from the chainsaw;

- The chain is installed in the holder (swivel support) with the links pointing towards the sharpening wheel.

- The required degree of the back angle of the upper blade is selected (50 ° or 60 ° depending on its type).

- The chain retainer (paddle) is adjusted so that it rests against the tooth to be sharpened.

- By marking the scale with degrees, the angle of sharpening of the chainsaw chain is set. It ranges from 25 ° to 35 °, and can also be equal to 10 ° for rigs intended for longitudinal cutting of wood.

- The head with the sharpening disc is smoothly lowered onto the chain and the sharpening depth is adjusted with a screw.

- The head rises and after all screws are firmly tightened, the device starts up.

- The grinding wheel is slowly lowered and the tooth is sharpened in several short passes so that the metal does not overheat.

- First, sharpening is carried out on one side, and then the caliper turns and the chain is processed from the second.

Once all the teeth of the chain are sharpened, it should be thoroughly cleaned of chips and dust, and then immersed in oil. This will significantly extend its service life.

Always check the depth gauges after sharpening the teeth. On most types of chains, the distance between the top edge and the teeth is 0.65 mm. The limiter affects the depth of the teeth cut into the wood, therefore, for high-quality and comfortable work, it is necessary to monitor its value.

Always check the depth gauges after sharpening the teeth. On most types of chains, the distance between the top edge and the teeth is 0.65 mm. The limiter affects the depth of the teeth cut into the wood, therefore, for high-quality and comfortable work, it is necessary to monitor its value.

How to choose a machine

When choosing a tool, you should pay attention to its power and number of revolutions per minute, as well as the diameter of the grinding wheel, since the purpose of the purpose depends on it. The speed affects the performance of the tool. For home use, devices with 3000 rpm are suitable, and for processing a large number of chains, you should purchase a more powerful machine - 4800-7500 rpm.

Similarly, with power, if you plan to use it only a few times a month, then it is better to take an average power, then it will not experience heavy loads and will last longer.

Similarly, with power, if you plan to use it only a few times a month, then it is better to take an average power, then it will not experience heavy loads and will last longer.

The price of a sharpening machine for chainsaws depends on its characteristics and configuration (the presence of a protective screen from sparks, head rotation, cooling system, automatic clamping of the vice, and so on). You should not buy too cheap models, especially if they are completely made of ordinary plastic.

Sharpen the chain once a year - a simple saw chain sharpener will do.